ASM-TF universal no-clean tacky soldering flux for hand-soldering and automated assembly (ROL0)

Automated Soldering Machines - BGA, solder paste printers, automatic dispensers, vacuum stencil cleaners

STIRRI®

SKU:TF-SSM-C05

En existencias

No se pudo cargar la disponibilidad de retiro

STIRRI® ASM-TF™ is a universal, no-clean tacky flux for leaded and lead-free soldering. Ideal for BGA, rework, hot air & automated electronic assembly. A high-performance industrial grade material designed for both leaded and lead-free solder applications. This versatile flux is the prosumer's choice for a broad range of soldering processes, including hand-soldering and automated assembly, as it features a proprietary HX-Booster™ package for superior oxide stripping and a QC-Aid™ optical tracer for easy quality control inspection under UV light. Activated residue is clear and benign, can be reliably left on the board, eliminating the need for post-soldering cleaning, while also conforming to J-STD-004C for no-clean formulations.

Product Description

Product Description

STIRRI® ASM-TF™ – The Original Classic No-Clean Universal Tacky Flux

The Prosumer's Choice for Rework, Automated and Hand-Soldering

STIRRI® ASM-TF™ is a high-performance, universal no-clean tacky flux engineered for both leaded and lead-free solder applications. This versatile flux is ideal for a broad range of soldering processes, including manual hand-soldering and automated assembly lines utilizing pneumatic dispensers, solder paste printers, BGA machines, and reflow ovens. The formulation includes our proprietary HX-Booster™ package coupled with a chloride activator for superior oxide stripping.

Featuring an RMA-grade performance, ASM-TF™ boasts an optimal viscosity and a light, creamy flux body, leaving a clear, benign residue that can be reliably left on the board, eliminating the need for post-soldering cleaning in many applications. It also incorporates a QC-Aid™ optical tracer, enabling instant visual cleaning Quality Control (QC) certification through inspection in the blacklight/UV light. The flux provides a nearly odorless formulation, enhancing workplace safety and comfort. For situations requiring residue removal, it is easily cleaned with common solvents such as isopropanol (IPA), acetone, or industrial no-clean solvents. Optimal cleaning results are achieved when the Printed Circuit Board (PCB) is still warm.

The HX-Booster™ package, which augments halogens, may cause the unactivated residue to exhibit temporary conductivity. This characteristic ensures superior soldering performance and can be fully addressed by optimizing the soldering profile with additional time and heat, or by cleaning the assembly. The activated residue is benign and fully conforms to J-STD-004C for no-clean formulations.

Key Performance Advantages

- RMA-Grade Performance: This flux boasts optimal viscosity and a light, creamy flux body, leaving a clear, benign residue that can be reliably left on the board. While classic RMA uses polymerized rosin, resulting in a darker color and residue, ASM uses hydrogenated rosin, which has similar properties but is extremely clear.

- Versatile Application: Ideal for a broad range of soldering processes, including manual hand-soldering and automated assembly lines utilizing pneumatic dispensers, solder paste printers, BGA machines, and reflow ovens.

- Superior Clarity: The translucent residue allows for an unobstructed view of solder joints and IC pins, offering ultimate control over the soldering process.

- Non-Corrosive: This flux is non-corrosive, and its activated residue is fully benign and can be left on the PCB.

- Excellent Component Hold: Maintains a strong tack to hold components in place, yet allows for easy repositioning with a hot air gun.

Suitable for:

General electronics repair, hand soldering, BGA rework, and automated soldering processes.

Compliance and Standards

- Classification: ROL0 (Halide-free <0.05%)

- Environmental Compliance: REACH-compliant and environmentally/health-friendly.

Formulation Details

- Rosin/Synthetic Resin Blend: A balanced blend of reprocessed rosin crystal and fully synthetic resin provides excellent soldering performance, minimal residues, and broad alloy compatibility.

- Low-Residue Characteristics: Ideal for applications where cleaning is challenging due to component density, equipment limitations, temperature constraints, or restricted access.

Manufacturing and Application

- Flux Application Method: The flux is designed for use with various modern dispensing equipment, including positive displacement and time/pressure systems, as well as manual application.

- Solder Alloy Compatibility: The flux exhibits excellent compatibility with a wide range of solder alloys, including SnAgCu and SnPb alloys, making it an all-purpose solution.

Ready for Implementation

While ASM-TF™ is designed as a no-clean flux, cleaning may be necessary prior to conformal coating to ensure optimal coating adhesion and long-term reliability, particularly in harsh operating environments. As a supplier of both fluxes and conformal coatings, we can offer expert guidance on selecting the appropriate cleaning procedures and conformal coating materials for your specific application. Contact us to discuss your requirements.

For even greater performance and modern features, explore our next-generation V3 and V4 series fluxes. V3-TF is the high-performance evolution adding REACH compliance and dual tracers (Visual QC-Aid™ and Olfactory QC-Aid™). While a reliable product, V3 has certain design considerations regarding its longevity and cleanability addressed in V4-TF, next-generation solution engineered to enhance the performance of V3. Its key advancements are AIRfree™ technology, which provides a splatter-free, consistent flow, and an improved solvent system with a higher boiling point for enhanced longevity under hot air and superior cleanability. However, if these enhancements are not necessary, we recommend you stick with the original ASM formulation to benefit from its proven, robust chemistry and much lower cost.

Idoneidad

Idoneidad

Automated soldering machines, BGA, hand-soldering, hot air rework

Designación

Designación

TDS - Ficha Técnica

TDS - Ficha Técnica

42-54 mPa/s (Malcom @ 10 RPM/25ºC (x 10³mPa/s))

Descargo de responsabilidad

Descargo de responsabilidad

La información contenida en este documento se basa en datos técnicos que creemos que son confiables y está destinada a ser utilizada por personas con habilidades relevantes bajo su propio riesgo. Los consumidores deben realizar sus propias pruebas para determinar la idoneidad de cada producto para su proceso particular y tomar medidas de seguridad. Los fabricantes/revendedores no asumen ninguna responsabilidad por los resultados obtenidos o los daños incurridos mediante la aplicación de los datos presentados.

Limpieza "sin limpieza"

Limpieza "sin limpieza"

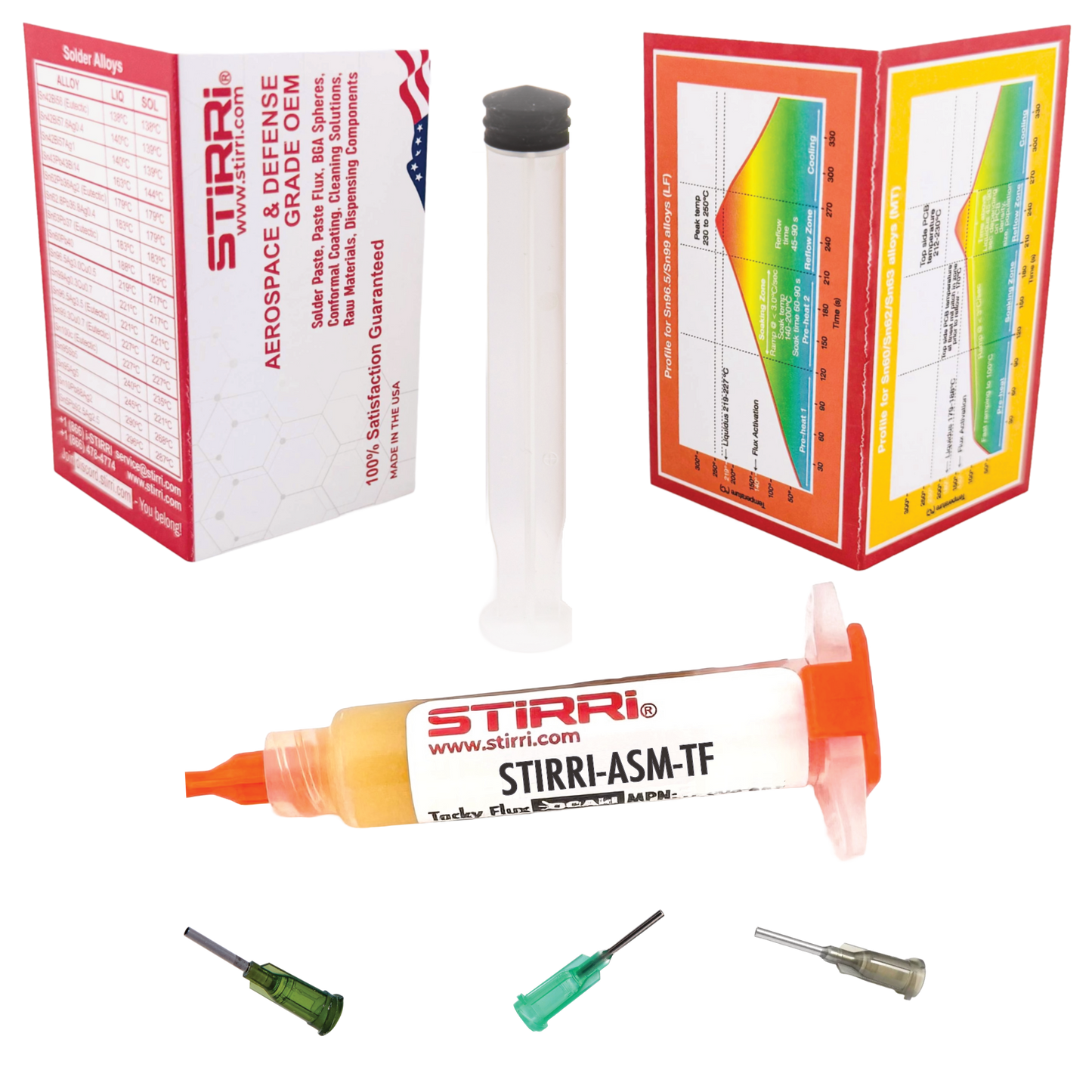

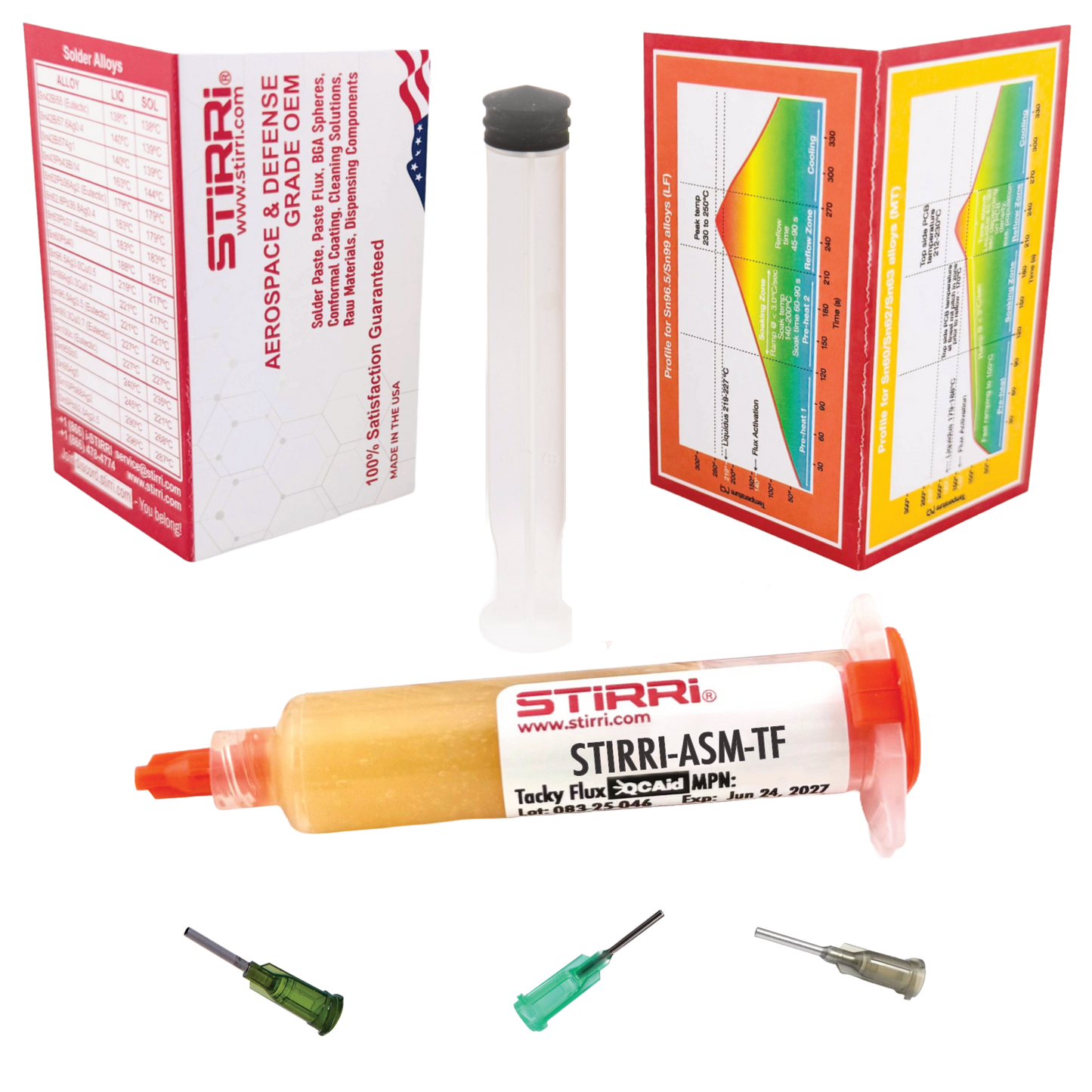

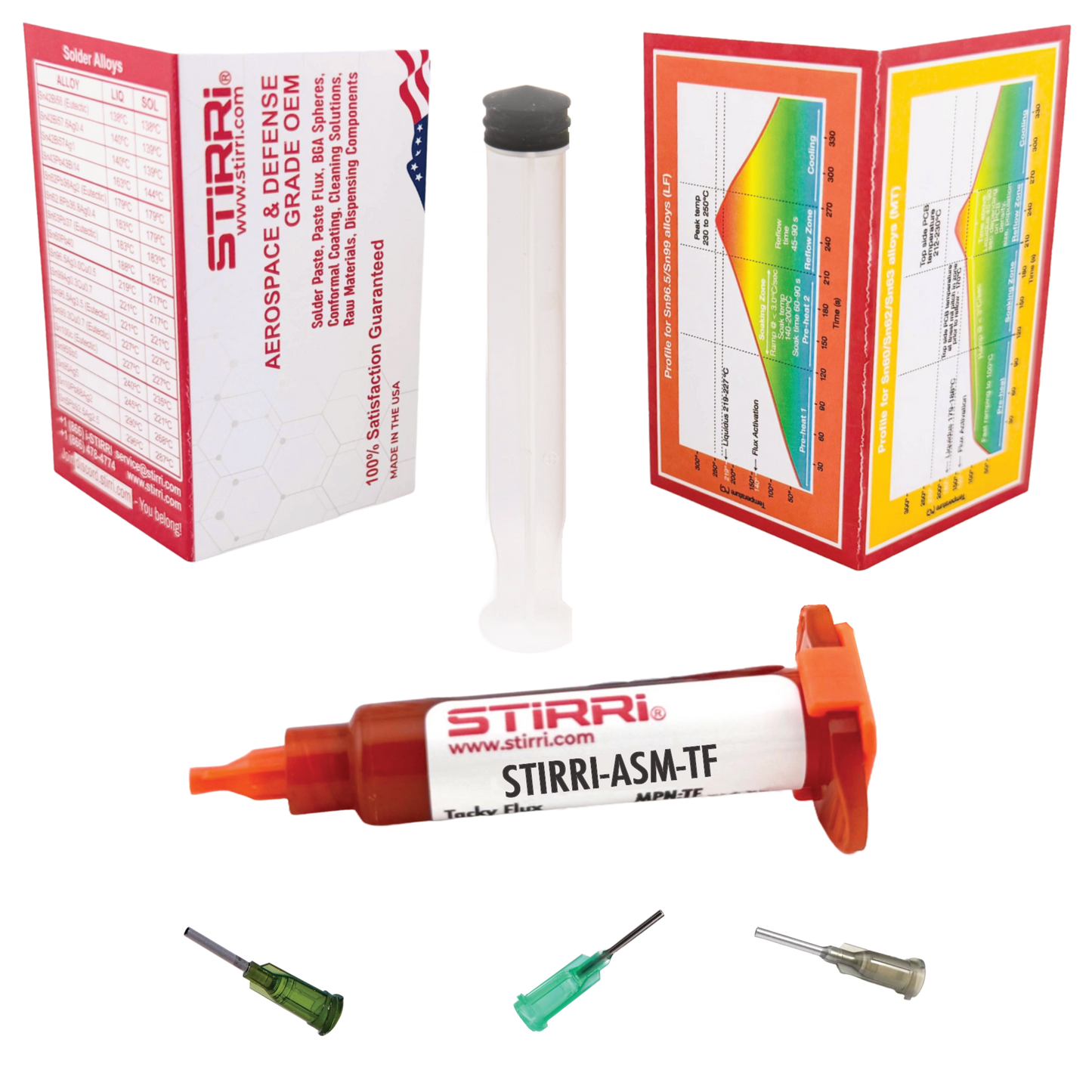

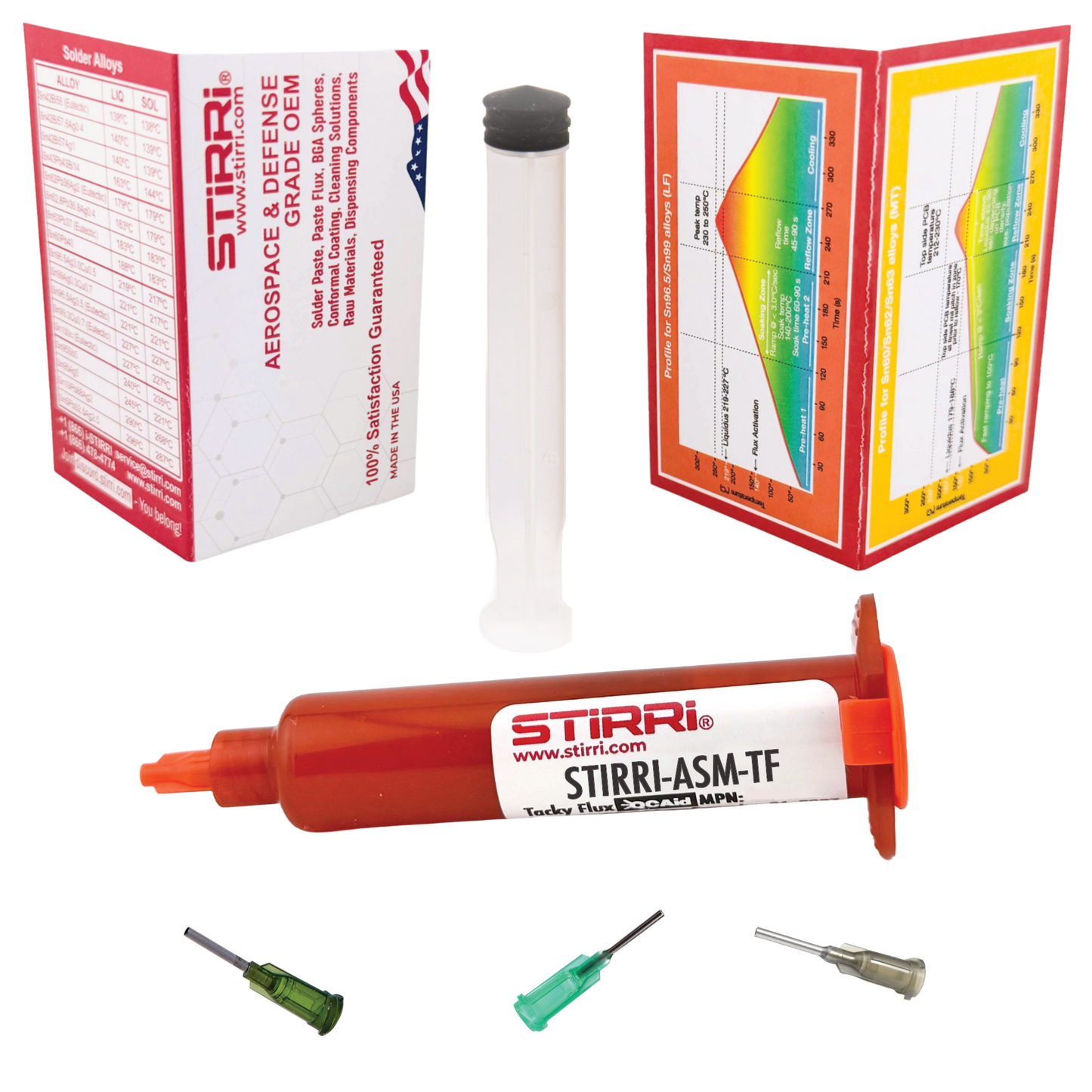

Kit de dispensación

Kit de dispensación

Este producto no incluye ningún kit dispensador: ¡una compra por separado!

El kit de dispensación es un complemento para la dispensación manual, que se utiliza para crear presión con un émbolo de forma similar a una jeringa médica.

Las jeringas de aire destinadas a máquinas dispensadoras neumáticas utilizan un tapón de pistón en lugar de un émbolo. ¡No retire el pistón ya que ofrece el mejor sellado evitando el contacto con el aire!

Cumplimiento

Cumplimiento

Este material está certificado conforme a REACH: no utiliza ninguna materia prima de la lista restringida de sustancias de gran preocupación de REACH.

Compartir

RFQ - Request For Quotation

Estas en buenas manos

Fabricado en los EE. UU. según los estándares industriales aplicables. ¡100% de satisfacción del cliente garantizada!

Liquid-proof the assembly with Nano-Coating - dries in less than 8 seconds

STIRRI HydraCoat™ is a liquid repellent making PCB liquid proof, instantly improving assembly value!

With an impressive droplet contact angle of over 113º, this nonconducting solution creates an invisible hydrophobic shield repelling weather, humidity, moisture - coated PCB continues to function even when fully submerged!

Broadly suited for consumer devices, automotive circuits, urban and landscaping lightning, LED, medical or electronic devices, marine, boating and yachting industries.

Dry to touch in less than 8 seconds, self cures in 24 hrs or 10 min in 60ºC chamber.

STIRRI's Conformal nano-coating ensures end-customer satisfaction while virtually eliminating assembly claims due to environmental or consumer liquid damages.